Life test is an electrical stress test that typically employs voltage and/or temperature to accelerate the appearance of wear-out reliability failures in a device. The objective of life testing is to evaluate whether failures caused by wear-out are likely to occur during the product lifetime and thus to estimate compliance of the device with the long-term reliability requirements

This test can be performed at the evaluation and qualification phase, its objectives and, consequently, its duration and the specific requirements being different. At the evaluation phase, the life test can be used to identify wear-out failure modes, so the test duration can be extended to 4,000 or even 8,000 hours. At the qualification phase, life test is used to determine the presence or absence of latent defects that could affect the long-term performance of the device and the test duration varies between 1,000 and 2,000 hours.

Characteristic of Life Test

Test duration, voltage, and temperature depend on the acceleration factor used for testing and on the activation energy of the failure modes under consideration. However, it is strongly recommended not to exceed the maximum junction temperature unless a specific monitoring setup is used.

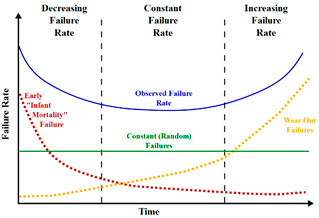

Tests are conducted within rated operating conditions should be conducted for a sufficiently long test period to assure that results are not characteristic of early failures or “infant mortality”, and periodic observations of results should be made prior to the end of the life test to provide an indication of any significant variation of failure rate with time.

We are able to select, design and manufacture our own hardware and software, including test circuit, biasing board, suitable zero insertion force test sockets, development of electrical test software, custom test fixtures, qualification test plans, etc.

Our expertise in the performance of life reliability test allows our customers to deepen their understanding of the fundamental wear-out mechanisms, detect design marginality combined with parameter drift and determine failure rates due to latent manufacturing defects. Life reliability test is carried out with strict adherence to applicable JEDEC, MIL-STD and ESCC specifications.