HAST is performed to evaluate the reliability of non-hermetic packaged solid-state devices that are likely to encounter humid environments during normal (ambient) operation. Also known as Pressure Cooker Test (PCT) or Unsaturated Pressure Cooker Test, the purpose of HAST is to evaluate the specimen´s resistance to humidity by raising the water vapour pressure inside the test chamber to a level that is drastically higher than the water vapour pressure inside the specimen.

HAST test reduces the time it takes to complete the typical humidity 85 ºC / 85% RH testing for semiconductors (96 HAST hours are equivalent to 1000 THB hours). This is possible by elevating temperatures above 100°C (usually up to 130°C) and increasing the pressure. Simulation of normal humidity tests can be performed while maintaining the same failure mechanisms.

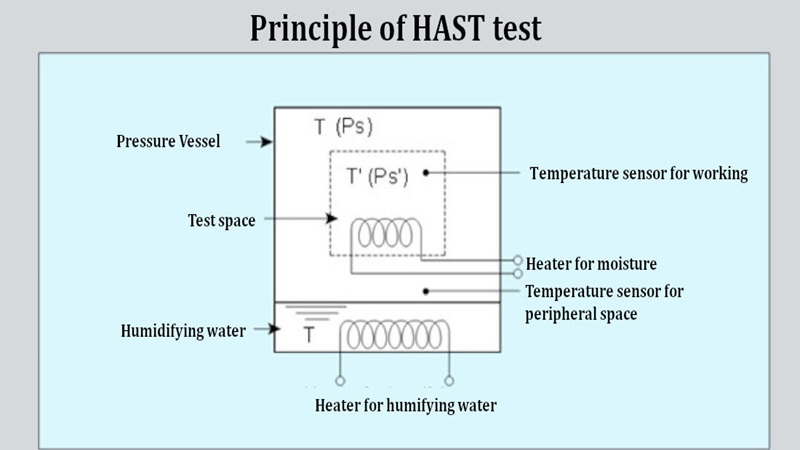

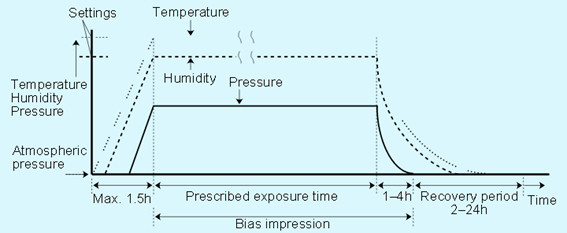

HAST test diagram

HAST test diagram

The test is considered as failed when the devices under testing exceed the parametric limits or their functionality which cannot be demonstrated under nominal conditions or in accordance with the applicable acquisition document.

The applicable test methods are the following:

- IEC 60068-2-66 (1994-6) Environmental testing. Part 2: Test Methods-Test Cx; Damp heat, Steady state (unsaturated pressurized vapor).

- IEC 60749 AMMENDMENT 1 (1991-11) Semiconductor devices Mechanical and climatic test methods 5C Damp heat, steady-state-highly accelerated.

- JEDEC STANDARD (1988-6) No.22-110 Test Method A110 Highly-Accelerated Temperature and Humidity Stress Test (HAST).

- EIAJ (Electronic Industries Association of Japan) ED-4701 (1992-2) (Japan) Environment and Duration test methods for Semiconductor Devices Method B-123 Unsaturated vapor pressure test.

ESPEC EHS-411M for HAST or Pressure Cooker Test

HAST has demonstrated to be an extremely efficient tool for screening and testing of components for space applications, reducing the execution time and ensures that the results are obtained efficiently.

The increasing use of COTS (Commercial Off The Shelf) parts in space applications requires a fast response time in case the product is screened. HAST can be considered a significant advantage in the two key elements of screening flow: time and representativeness of results.

Alvaro Ricca Soaje

Álvaro is a Hardware Engineer at the Electrical Measurement Laboratory of Alter Technology. He provides technical support and hardware solutions for electronic designs. His work involves the development, analysis, and validation of circuits in demanding environments. He contributes to ensuring the reliability and accuracy of advanced electronic systems.