PA plan Vs PPCP

In other posts of this blog, we have extensively talked about Product Assurance (PA) Support, PA Plan and approach of PA to New Space. Now, the time has come to put all of this “on the ground” and take things into practice during procurement for a space project.

Applicable to all subsystems of the program, the PPCP defines the technical provisions and all the associated procedures for EEE parts, including all the engineering and quality assurance aspects. This allows for establishing a homogeneity regarding parts quality and dependability during all project procurement phases.

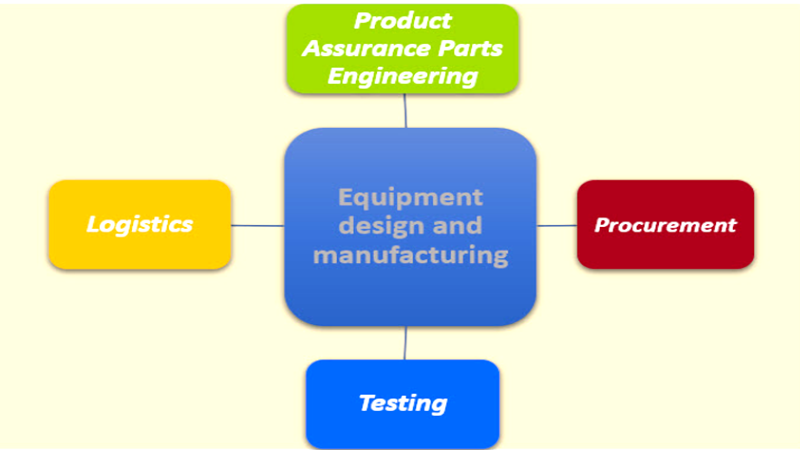

The objective of a PPCP is the identification of responsibilities, activities and detailed product assurance methods for the selection, standardization, procurement, testing and control of parts, in the most efficient way in terms of cost, schedule and required quality level.

Regarding to its applicability, the PPCP plan is normally applicable for all the activities related to the EEE components procurement from phase B2 to phase D of the project, covering the following aspects and assessing their implementation:

- Pre-procurement activities: includes DCL analysis, evaluation, specification preparation, PAD preparation and quotation.

- Procurement activities: order revision and placement, manufacturer’s follow-up, Precap and CSI performance and parts reception.

- Post-procurement activities: Data review, additional testing (DPA, RVT, Incoming Inspection), CoC issuing, packing and delivery of the parts.

In those cases where there is not a dedicated PPCP plan, the main document applicable for reference becomes the ECSS-Q-ST-60 standard, which includes the criteria for selection and test (among other points) for the different components as a function of the class mission that could be from class 1 (the highest quality level and most stringent requirements) to Class 3 (the lowest quality level considered).

Having explained this and taking previous posts into account, it is easy to assess the difference between a PA Plan and PPCP: While a PA Plan defines the programmatic PA requirements for a certain Space Project (including Quality Assurance, Software Product Assurance, Safety Assurance, Dependability, EEE parts quality, selection and procurement, material parts and process selection control, etc), the PPCP defines the practical way to comply with the PA requirements related to EEE parts.

As per Alter Technology wide experience within the Space market, we are able to offer, as part of our PA support services, not only the performance of procurement in accordance with a PPCP but also the development and delivery of the PPCP for a specific project.