Engineering projects are usually very demanding in terms of technical performance, schedule, reliability and costs. In particular, space missions are even more critical given the typical non-recurrence driving the costs even higher, the impossibility of making any maintenance or repairs, and the difficulties of the environment (temperatures, radiation exposure, vibration on launchers…).

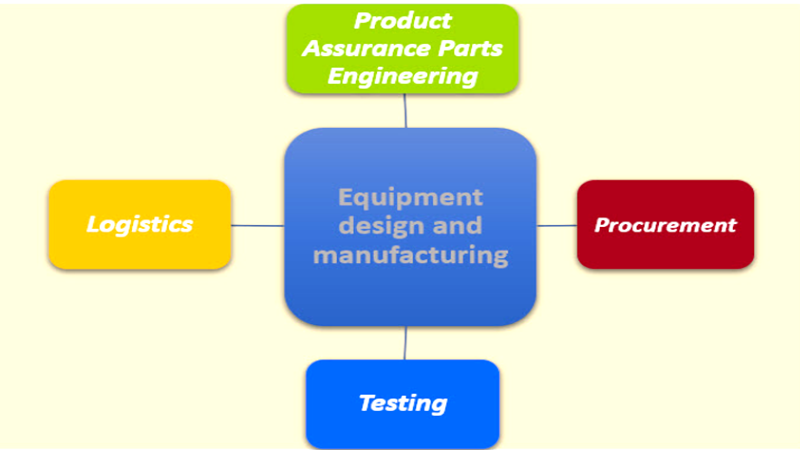

Having considered all these demands, space projects require the implication of dedicated personnel on Product Assurance. Their main goal is fail-proofing the projects/missions by making sure that electrical components, mechanical parts, materials and even all different processes used on the manufacturing are in line with the mission goals. The position of these PA Engineers is key to the success of any space mission, assuring compliance with their requirements.

Focusing on EEE parts, the selection of these parts was restricted to qualified components, but the trend is changing in the last few years, mainly on science missions, where the technical performance of non-qualified parts gives the Instrument designers much more capabilities to meet the requirements. Once the project approves a Technical Justification, PA Engineer will need to review the applicable tests that will lead to the final acceptance of these parts.

Linked to this trend, New Space projects are also willing to use lower quality levels of EEE parts, (out of classical Class 1-2-3 of ESA projects) such as automotive components.

For each project, a PA Plan shall be prepared containing all activities in accordance with the end customer requirements. This PA Plan shall be approved by customer and be followed through the whole life of the mission.

There are standards including requirements for Product Assurance. On ESA side, applicable document reference is ECSS-Q-ST-10C.Rev1. A template of a PA Plan is also included as an annex to this document.

ALTER has a team of senior engineers with an extensive experience in many programmes assuring the mission is on track according to PA Plan. If you want to subcontract these activities acting on your behalf, please contact us.