The main challenge for EEE parts performing on Space projects is to withstand the extreme and harsh environment they must work in. This involves performance in vacuum conditions, extreme temperature values and radiation environment. On this regard, the main difference between space parts and COTS is that the first ones are prepared to operate in this environment. This involves not only technology, process and materials, but also additional testing required on the parts to assure the performance level during the mission.

On this context, the concept of Product Assurance (PA) stands as a fundamental pillar. Product Assurance can be defined as the set of requirements that materials, processes and parts must comply to assure proper performance of the equipment during the mission lifetime. These rules are gathered in a PA Plan.

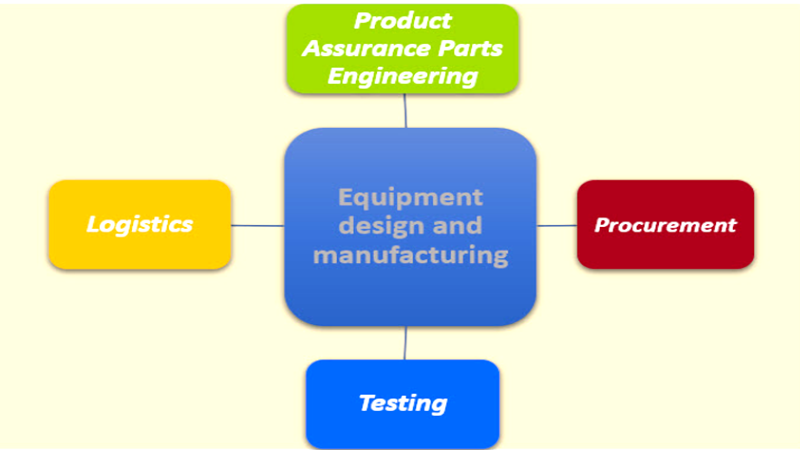

PA Support are the group of activities dedicated to verify the PA requirements of a Project are met. These activities might involve some of the following:

- Technology and product assurance assessment based on mission profile, from COTS to Class 1 projects: consists of a study to assess which requirements are needed based on the type of project, orbit, mission lifetime, etc.

- Analyze and review requirements and prepare PA and safety plan.

- Engineering support to all activities, verification compliance to Product Assurance requirements (payload and platform). This task focuses on helping the equipment designers to comply with the PA Plan.

- Technologies and Parts selection to meet the customer/project requirements. Narrowing the scope, this task could be summarized as “from calculation to market availability”.

- Type reduction and standardization (fewer lines to procure, leading to an easier handling and follow-up, reduction of unit prices…). This task allows a homogenization between different designers, leading to cost savings and smoother procurement.

- Generation, review, discussion and approval of evaluation, qualification, LAT (Lot Acceptance Testing), DPA (Destructive Physical Analysis), QCI (Quality Conformance Inspection), RVT (Radiation Verification Testing) and up screening plans, justification documents and any document which may be necessary for PAD approval/fulfilment of project requirements.

- Organization and participation to Parts Control Board and other meetings /telecom as required by the project

- Preparation and management of RFWs (Request for Waivers), RFDs (Request for Deviations), NCRs (Non-Conformance Reports) and participation in NRBs/MRBs (Non-Conformance Review Boards/Material Review Boards).

- Technical support and review of radiation analysis, WCA (Worst-Case Analysis) and further EIDP (End Item Data package) documents related to EEE parts.

- The follow-up to users and manufacturers in order to close any action that has been agreed during a PCB, NRB/MRB.

- Generation and maintenance of consolidated DCL for the Unit. As more than one team may be involved in the design of equipment, consolidation of the DCL allows to keep traceability of the parts to be procured and the reduction of the part performed.

- Alert and Obsolescence Management during the project. During a Project procurement phase, it is not unusual that some parts are obsoleted by their manufacturer or that an alert concerning a certain type arises, so it is important to keep track of them.

- Audits and inspections at manufacturers and supplier premises as part of evaluations. Independent Precap and buy-off inspections if required.

- Training courses (quality assurance, EEE space components engineering, radiation…) and others.

From the list above, it can be easily understood how important it is for any team involved on a Space Project to have the proper PA support on the definition/compliance to PA Requirements.

In this sense, Alter Technology, with a wide experience of 30 years in the Space business and has supported many of the main European Space Projects during this time, can provide PA Support to customers interested on this service.