ALTER has extensive experience in EEE parts engineering, procurement and storage.

Long-term storage was one of our early studies. In 1993, in the frame of COLUMBUS project, we got an ESA contract to assess the “Long Term Storage for High Reliability Components”.

Procedures and a storage area were put in place.

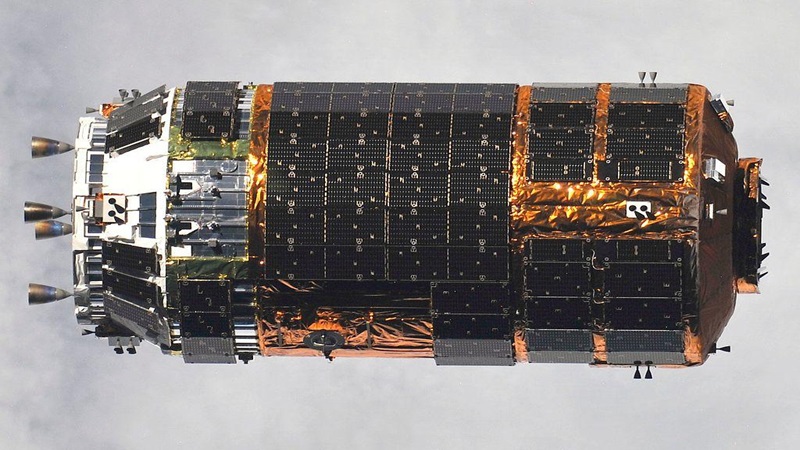

ALTER perform for the European Space Agency (ESA) the official storage of parts surplus coming from different ESA projects. ATV and HTV projects; ATV parts procurement performed in 1999 to cover needs for 4 flight units. The scheme was repeated in 2003. Same approach for HTV project.

Circuit Design: Main parameters of an optocoupler

Absolute maximum ratings

We use the MIL and ESA procedures relevant to manage the storage process and their associated tasks. As reference see:

- ESCC 24900 “Minimum requirements for controlling environmental contamination of components”.

- ESCC 20600 “Preservation, packaging and dispatch of ESCC electronic components“.

- IEC 61340-5-1. Electrostatics – Protection of electronic devices from electrostatic phenomena –

- MIL-MIL-PRF-81705 Barrier Materials, Flexible, Electrostatic Discharge Protective, Heat-sealable, etc.

- MIL-STD-19491 “Packaging of Semiconductor Devices”.

- MIL-STD-39028 “Packaging of Capacitors”.

- MIL-STD-55330 “Packaging of Connectors, Electrical and Fiber Optic”.

- ECSS-Q-ST-60 “EEE Components”.

- ECSS-Q-ST-60-14 Relifing Procedure – EEE Components”.

- ECSS-Q-ST-70-01 “Cleanliness and Contamination Control”.

- ECSS-Q-ST-70-20 “Determination of the Susceptibility of Silver-plated Copper Wire and Cable to “Red-plague” Corrosion”.

Storage Degradation Mechanisms

Device degradation occurred during storage come from different sources:

- Chemical degradation

- Mechanical degradation

- Thermal degradation

- Combined effects, the most relevant

Component related

- Component technology

- Component package: hermetic, plastic,…

- Lead material and finish

- Supplier packaging

- Handling prior to storage

- Device cleanliness

- Device ESD sensitivity

Storage related

- Temperature range and stability

- Humidity range and stability

- Industrial / corrosive atmosphere

- Storage duration

- Handling

- ESD management

- Storage packaging

- Special considerations: MBB bags, dry storage, N2 cabinet, moisture indicator, desiccant pouch, etc.

HTV project.

In all the cases, the parts were selected, ordered, received, tested, packed, and stored with a periodic verification (when required), supplying the components to the different equipment manufacturers through programmed deliveries.

The degradation can vary severely from one device to another in the same environmental conditions.

Long Term Storage, Affecting Factors

EEE components selection:

- Screening and quality level: commercial, industrial, MIL (QML V, QML Q, Y, S,…, 883), ESCC.

- Qualification level: qualified, non qualified, EPPL, automotive, …

- LAT / QCI level

- Maximum age (date code restrictions)

- Package type, lead material,…

- Obsolescence

- Past experience: preferred manufacturers, types, special testing …

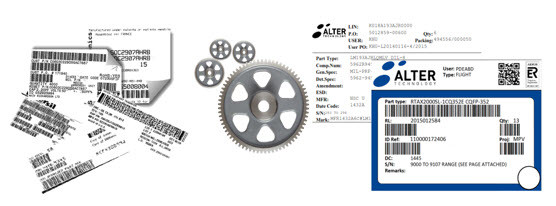

Device Packaging and Identification

We must use the right materials and processes to pack, re-pack the lots and prepare the kits in the most suitable way to support the next operation step: long term storage, delivery, assembly, etc.

The packing must consider the available procedures for example: IEC 61340, MIL-B-81705….It is needed to have available techniques to cover the spread range of components types: trays, bars, tape & reel, preformed boxes, MBB bags, vacuum and N2 purge sealing,…

Long-term storage services at ALTER

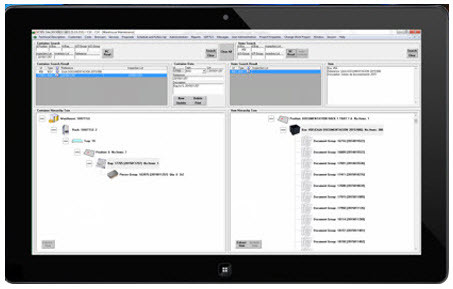

The warehouse management and control system (WMS) features:

- Controlled environment according to ESD requirements of IEC 61340-5-1:2016

- Temperature

- Humidity

- Smoke and fire detection plus extinguishing system

- Access control and security systems

- ESD store management: floor, table, ground connections, conductive or static dissipative materials use,…

- Special storage conditions: dry cabinet,..

- Housekeeping rigorous procedures, etc..

- Items are packaged into Static Shielding Bags or Moisture Barrier Bags

- Controlled conditions of temperature (+22°C ± 3°C) and relative humidity (55% ± 10% RH)

- EAN 128 BarCode codification

Shuttle Store System (SSS)

Moving up to 15.000 lots/year, the SSS is equipped with the latest technology on inventory management:

- Labelling and full-traceability

- Integration with ERP-SAP

- Restricted user profiles

- User record

- Touch screen and video controls

- Text-to-speech technology

- Motorized vertical shuttles

The SSS features a Kardex system and offers more than 110 m2 and up to 12 meters for the storage of fast-moving items.

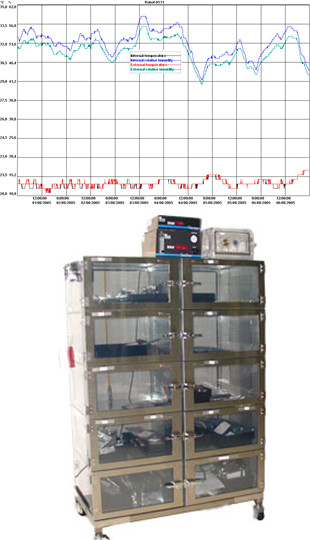

Nitrogen Desiccator Cabins (NDC)

- Cabins are optimal for the storage of moisture-sensitive devices, such as PEMs, dice and wafers

- RH <10%

- Controlled temperature conditions

Seven desiccator cabins featuring Terra Universal purge and Nitrowatch systems, and connected to an on-site N2 generator with an auto-refillable cylinder are available for the storage of fast-moving items.

Long-term Storing Area (LTS)

A large area of 200m2 is available.

- All systems are electrically grounded and the containers are made of conductive material, allowing a safe storing process.

- The inventory system is connected to the ERP, and the restricted access to the facilities guarantees a secure storage.

Full traceability, labeling & storage

ALTER offers an extension of your storage facilities with a reliable customized labelling service with real-time monitoring of the components as well as full access to the document management system through the User Area.

Additional services such as regular reviews, obsolescence control, relifing tests, license retransfer and express delivery are also available under request.

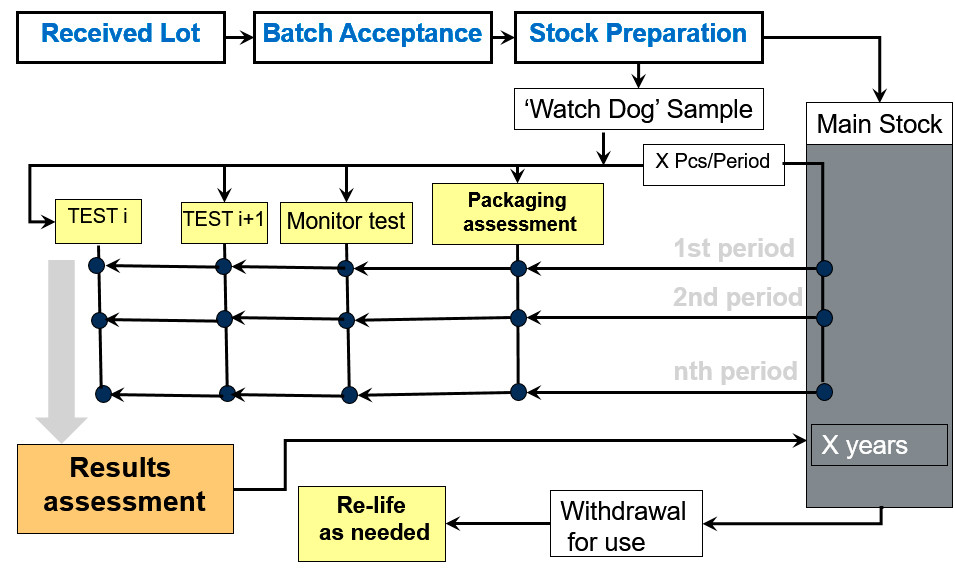

Stock Monitoring and Verification

David Nuñez Teruel

David Núñez Teruel is a seasoned aerospace professional with over 25 years of experience. He leads the High-Reliability Semiconductor Division at ALTER and is known for promoting the use of COTS components in space. He actively supports innovation, leads conferences, and collaborates with universities through initiatives like the USECHIP program for microelectronics training.