We have now learnt about the importance of Detail- Procurement specifications. However, we may still be lost on how to produce one, even if we know they must include electrical measurements and maximum ratings, mechanical requirements, testing flow, marking, range of components affected, derating information…

Some important inputs we need for developing a Detail Specification are as follows:

PA requirements

These are the Product Assurance rules the component must be compliant with, and therefore a core asset to write our specification. These requirements are of course influenced by the Class (1, 2 or 3) of our project.

Frame of the project

Is the project a European-based project? Is it a NASA one? Is the specification for custom development or a commercial Space project? These questions may not seem important at a first glance but are key to decide a template for our specification. For example, if the parts are intended for an ESA Project, it may be interesting to use an ESCC Detail Specification as a template. However, the decision of the template to be used is also highly influenced by…

Parts manufacturer

If the part manufacturer is European, it seems a good idea to follow the ESCC specification system template. On the contrary, if the manufacturer is USA based, using the DLA MIL specification systems seems more appropriate. Again, this is more like a tip, as it is not unusual that some European manufacturers manufactures can provide MIL grade QPL parts as well as ESCC QPL parts.

Component family-group

The next step, once the general specification system has been selected, is to go down on the specific family of our component. Generic specifications are different in testing, parameters definition and important features from one component family to another (for example, connector specifications may not have similar content to microcircuit specifications). Detail specifications go down on a specific subfamily. Therefore, if the component family group is known, we can choose a specification for similar components as a template.

Now a proper template is selected, it‘s time to fill it with the particular mechanical and electrical characteristics of our component, including maximum ratings and operating conditions, package, dimensions, marking, materials, ordering guide, radiation sensitivity…and, of course, testing. Regarding this, we can include them as deviations from the requirements of the Generic Specification or in the absence of a clear one fully define them (including methods, success criteria) on our Detail Specification, in accordance to our PA Plan.

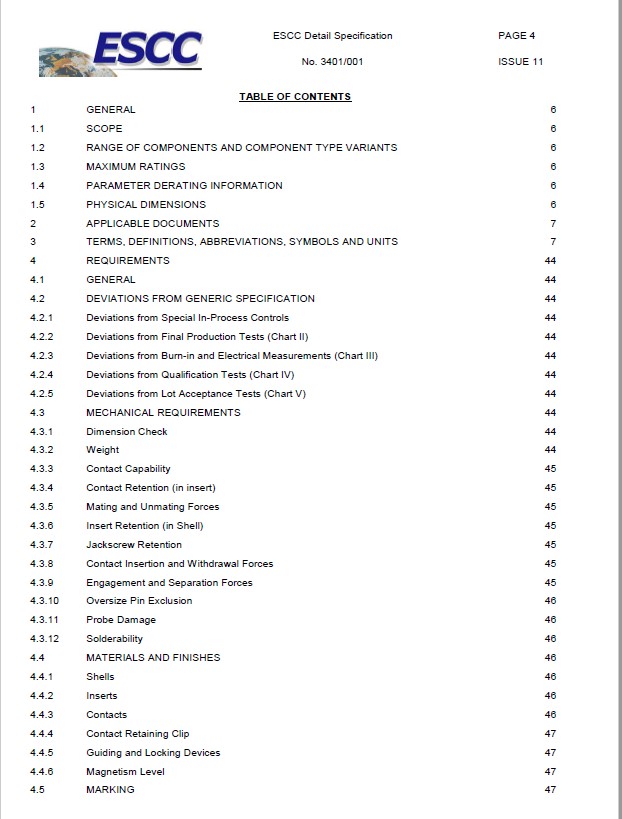

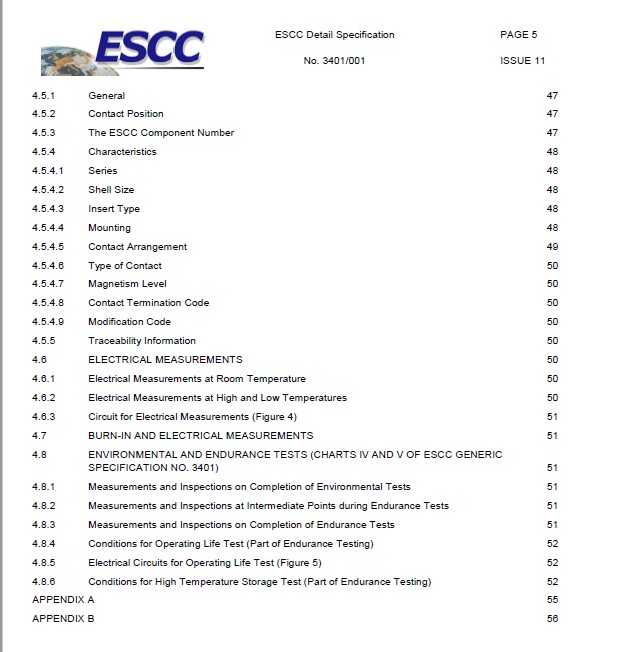

As an example, here below, we can see the index for detail specification ESCC 3401/001, showing the requirements for ESCC Sub-D type connector: