The purpose of Bond Pull test is to measure bond strengths, to evaluate bond strength distributions and to determine compliance with specified bond strength requirements of the applicable acquisition document in order to ensure the proper manufacturing process and long-term reliability of the bonds under stress conditions, such as vibration, shock, thermal cycling or wearout phenomena.

Bond Pull test is applied to the wire-to-die bond, wire-to-substrate bond or the wire-to-package lead bond inside the package of wire-connected devices bonded by soldering, thermo-compression, ultrasonic, or related techniques. It is also applied to bonds external to the device such as those from device terminals-to-substrate or wiring board; or to internal bonds between die and substrate in non-wire-bonded device configurations such as beam lead or flip chip devices.

The methodology for this test consists in applying the specified stress to the bond, lead wire or terminal as required in the specified test condition. A calibrated measurement and indication of the applied stress is provided by equipment capable of measuring stresses up to twice the specified minimum limit value.

All bond pulls shall be counted and the specified sampling, acceptance, and added sample provisions shall be observed, as applicable, depending on whether the test is to be destructive or non-destructive.

The destructive bond pull test determines the minimum force required to break the bond while the non-destructive testing ensures that no bond is broken, which is achieved by applying a specific force depending on on the type of device, the wire diameter and other factors defined in the product specification and the applicable test method.

Different types of test conditions are offered, depending on the bond and the device. For example:

- Bond peel

- Wire pull (single bond)

- Wire pull (double bond)

- Bond shear (flip chip)

- Push-off test (beam lead)

- Pull-off test (beam lead)

- Wire ball bond shear test

Any bond pull which results in separation under an applied stress less than the required minimum bond strength for the indicated test condition, composition, and construction shall constitute a failure for destructive and non-destructive bond pull.

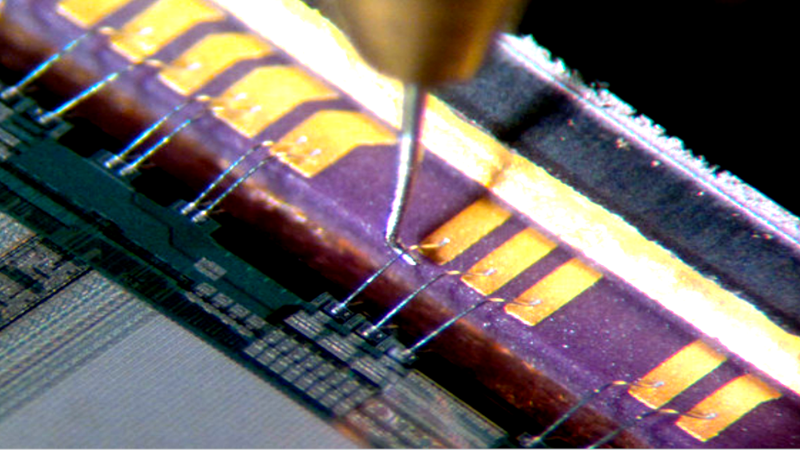

FIGURE: Wire bond strength test (Bond Pull test)

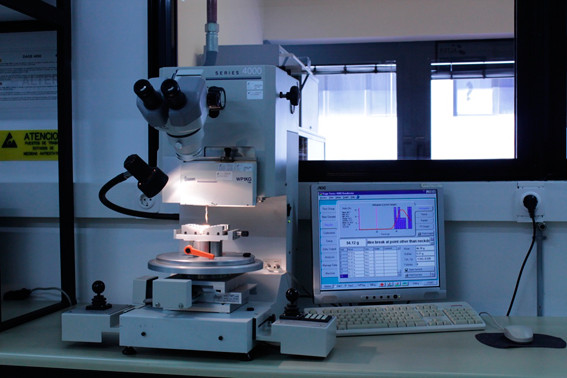

FIGURE: Bond pull test & die shear tester