The webinar provides a brief overview of some basic elements that influence the definition, development and conclusions of a Failure Analysis. You will acquire, for example, and in a friendly way, the knowledge to distinguish the different failure modes through real images of each of them.

We will present some of the technical capacities that a laboratory should have in order to carry out the different tests that are part of a test sequence defined for an FA, as well as some real examples carried out by Alter Technology during its more than 30 years of developing its activity in the aerospace sector.

The webinar addresses the following issues:

- Definitions: Reliability; Failure Rate; Failure Mechanism vs Failure Mode

- What a Failure Analysis is and what previous data we need to define an appropriate sequence of tests so that we can correct or prevent the failure in the future?

- The philosophy behind a Failure Analysis. Highlight

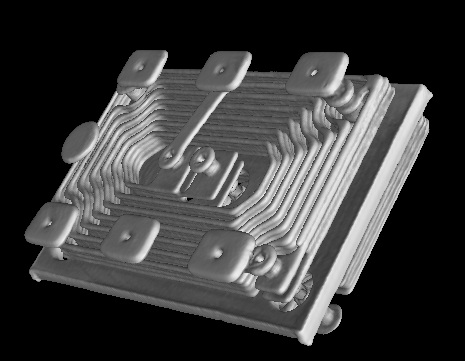

- Failure Analysis Procedures For Microcircuits (based on MIL-STD-883, Method 5003)

- What are the main failure modes? What are the implications and consequences of each of them?

- Examples of some real Failure Analysis performed by ALTER. Testing Capabilities.

Dimas Morilla

Dimas Morilla is Head of the RIT (Receiving and Incoming Testing) and DPA/FA Laboratories at Alter Technology, with two decades of experience in the aerospace sector. He holds a degree in Physics (Electronics Specialty) from the University of Seville, where he was awarded for the best academic record in his class. Since 2004, he has supported major European space programs including ATV, Herschel-Planck, Sentinel-3, Bepi-Colombo, and Solar Orbiter. His expertise spans a wide range of inspection and analysis techniques such as CSAM, SEM, PIND, and microsectioning. Dimas also holds multiple ECSS certifications in high-reliability soldering, crimping, and inspection of EEE components.