Thermistors/Resistance Temperature Detectors (RTD) using platinum-finished leads are widely used in the space market and have provided service to many scientific missions. The use of platinum leads allows for the covering of wide temperature ranges with good accuracy and stability and, therefore, a suitable performance in harsh environments. On the other hand, platinum leads cannot possibly be soldered with standard methods due to the lack of good wetting of platinum with Sn/Pb 63/37 dissolution and standard fluxes.

In this regard Platinum Temperature Sensors Solderability issues, several solutions have arisen possible in order to solve this issue, the most important ones being:

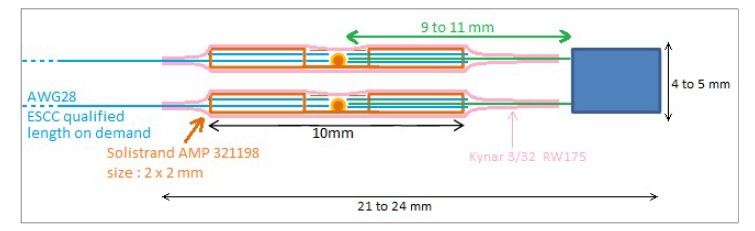

- Assembly by crimping based on “crimping of high-reliability electrical connections” iaw ECSS-Q-ST-70-26C. The principle of this solution is the following:

This procedure has been certified by CNES, and such certification has been considered as a qualification document for some ESA programs.

This procedure has been certified by CNES and such certification has been considered as qualification document for some ESA programmes.

- However, as the platinum used on the thermistors is too soft for crimping, the assembly technique preferred by some manufacturers is laser welding.

- A variant for this crimping option, consisting of soldering plus wrapped additional wire, was also certified by CNES and considered as a qualified solution on some projects. In this option, an additional wire is wrapped around the lead, and then soldering is performed.

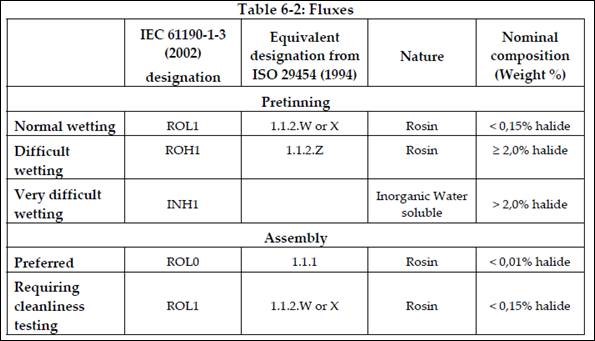

- The traditional option is assembly by soldering. As commented before, platinum finished leads cannot be soldered by standard methods by welding with Sn/Pb 63/37. However, soldering by using different fluxes has been accepted in the past by ESA for some of their missions as long as the requirements for fluxes to be used for pretending and assembly listed in ESA Standard ECSS-Q-ST-70-08C are met. Those requirements are summarized in below table.

ESA accepted the use of the following fluxes for a recent project of Platinum Temperature Sensors Solderability issues:

- For Pretining, Flux IF2005C/IF2005M, classified as ROL0 in accordance with IPC J-STD- 004.

- For Assembly Flux Kester 285, classified as ROL0 in accordance with IPC J-STD-004.