When selecting a current-sense resistor, there are many subtleties behind the scenes. What seems a very simple task actually isn’t at all.

Current-sensing techniques are intrusive, meaning that they will somehow affect the system’s performance. It’s usually necessary to insert “something” in the middle of the path that goes from the power source to the load through which the current that we need to monitor flows.

Finding the right trade-off for accurately measuring the current flow through a load sometimes constitutes a real challenge. Everything gets even more complicated under extreme conditions, like outer space, where it is indispensable to guarantee maximum reliability, precision, and longevity.

They are different current-sensing methods like using current transformers, hall-effect sensors, or just a simple conductor (i.g. PCB tracks), but this article will be focusing on the use of current-sense resistors.

While most of the time, resistors are basically used to regulate current, a current sense resistor is used for monitoring current. This completely different change of purpose set some of the basis in terms of attributes that must be looked at in a resistor to perform this function, such as:

A low resistance value is desirable. By applying Ohm’s law at a given current, we can see that a larger resistance value will result in a larger voltage drop, which means more energy will be dissipated due to the resistor’s self-heating, which is directly translated into wasted power that was delivered to the load. Unfortunately, choosing a resistance value that is too low will impact the voltage reading accuracy since the solder resistance in series with the resistor connections will considerably affect the overall resistance value.

Low-ohmic precision and power resistors for aerospace applications. (Courtesy of Isabellenhüette)

Tight resistance tolerance and a low-temperature coefficient resistance (TCR) for long-term reliability and performance. Self-heating will cause drift from nominal’s resistance value. In applications where resistors can be exposed to extreme temperature changes, such as Space, the selected resistor must have a suitable TCR, down to about ±100 ppm/°C (equal to 0.01%/°C). The TCR drift is dependent on construction technology, and in today´s market, it is possible to find a wide variety of them, like wire wound, thick film, thin film, metal foil, and so on.

Each technology allows different resistance values for a given size, so the designer must choose carefully based on the design restrictions (thermal dissipation strategy). In high-power applications, size matters, meaning that physically larger resistors are the only way to handle high current levels.

The resistor power rating must be sized for the dissipation, considering the average continuous current going through the load and short duration high current pulses that are under the resistor’s high peak power rating.

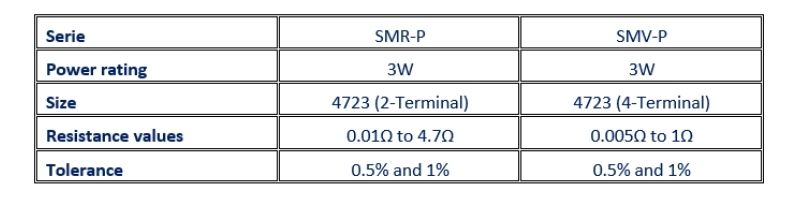

For this reason, high-power rating current-sense resistors are available with resistance values from a few milliohms. For example, the SMR-P (2-Terminals) and SMV-P (4-Terminals) series of low-resistance metal-foil power resistors handle up to 200 A and offer power ratings up to 3W, with resistance values from 0.005Ω to 4.7Ω, and its special construction features TCR limits of:

- -55°C to 22°C: -110; +0 ppm/°C

- +22°C to 170°C: ±60 ppm/°C

- +22°C to 170°C: ±50 ppm/°C (R ˂ 0.01 Ω); ±30 ppm/°C (R ≥ 0.01 Ω)

Isabellenhüette takes the most stringent quality standards and individual requirements (ESCC 4001 or MIL-PRF-55342) into consideration so that the power and precision resistors can be used in the aviation and aerospace industries. In addition, the SnPb tin-plated contacts prevent the formation of whiskers, thus ensuring safe use of the components, even under extreme conditions. They also provide a layout recommendation for the best current-sensing accuracy.

As mentioned before, low-valued current-sense resistors can experience an additional error caused by the solder resistance in series with the resistor connections. If the resistor is going to be board-mounted, the connections will likely be made of copper, and this material has a much higher TCR (+3900 ppm/°C) than not only any current-sense resistor but any standard resistor as well. There are meticulous PCB layout techniques to minimize this error when using a 2-terminal resistor, but a 4-terminal (Kelvin) resistor solves this problem. A 4-terminal current-sense resistor has separate terminals for current flow and voltage drop measurement, guaranteeing higher current measurement accuracy.

At high current levels, this configuration becomes almost mandatory because significantly small resistor values can be required to avoid vast amounts of heat dissipated since dissipation is proportional to the square of the current.

In some ultra-high-power applications, paralleling 4-terminal (Kelvin) resistors may be an appropriate solution to distribute the heat while increasing the precision of the overall resistance value. If you are interested in continuing reading about this, the article below develops this topic extensively!

Wrapping Up

In the end, picking a current-sense resistor it is a matter of choosing the right trade-off depending on your application. The chosen part should never impact the performance of your system.

Isabellenhüette has been one of the world’s leading providers of low-valued precision and power resistors, supplying the aerospace industry for many years.

Javier de la Ossa Fernández

A data scientist with a decade of experience in aerospace and high-reliability industries, now specializing in digital marketing and analytics. Armed with a background in Electronics Engineering, applies AI and data-driven strategies to deliver innovative and impactful solutions.