Vibration Testing for Small Sats

- Posted by doEEEt Media Group

- On April 2, 2022

- 0

Vibration testing is intended to reproduce the vibrations experienced by the satellite during the launch phase in order to make sure that the satellite will not suffer during this phase.

ALTER is a highly qualified laboratory to perform VIBRATION TESTING. This is a very specialized field where ALTER is a highly qualified laboratory performing numerous tests in EEE Parts. To do this kind of service, we have extended and qualified laboratory accreditations that bring to your needs secure and safe work. These include the ones related to Small Sats and units. The applicable standards are:

- ISO 19683 refers to ISO 15864.

- Launcher’s requirements

Vibration Test flow

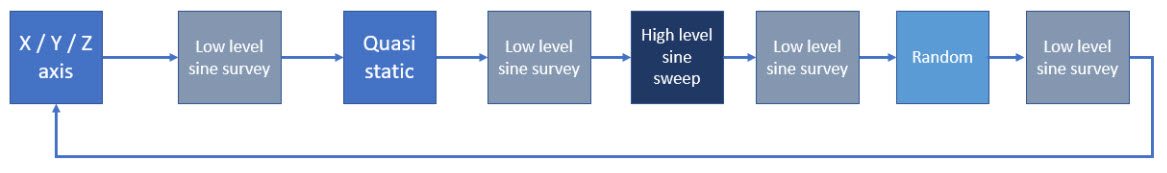

ALTER offers full Laboratory Equipment for any needs with an expert group that will support you throughout the process. Typical vibration tests include quasi-static, sine sweep, and random tests in all 3 axes, with an eigenmode survey (low-level sine sweep) and possibly functional tests after each test to check for structural and functional damage.

- Quasi-static vibration tests are a proxy to static acceleration tests intended to reproduce the first stage of the flight when the launcher is accelerating. However, static acceleration can be simulated just in centrifuge stations, which are scarce, complex, and expensive. Therefore, this test is often replaced by the quasi-static profile, consisting of a series of “bumps” at a low frequency and duration of several minutes.

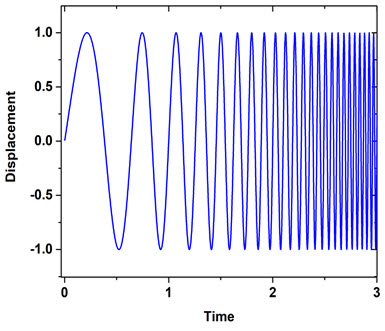

- Sine sweep intends to excite and stress every single vibration mode in a given frequency range (typically low, 5-100Hz to excite the structure of the CubeSat) with a high acceleration level to ensure that all failure modes of the structure are tested.

GET IN TOUCH TODAY!

Do you have questions? Contact us!

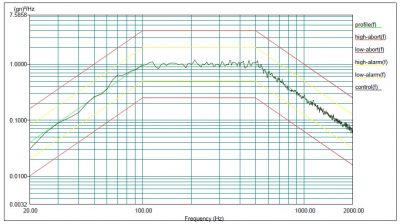

- Random vibration intends to reproduce the mechanical environment inside the fairing, which is a broad spectrum and difficult to reproduce exactly.

- Low-level sine sweep is intended to detect changes in the vibration spectrum of the CubeSat, which are indicative of a displacement of the equipment, loosening of screws, or cracks in the structure.

A typical vibration test flow is shown in the following figure:

The launcher fixed the test levels because the vibration levels are typical of each launcher. In CubeSats, they are often deployed from a container provided by a third party, which can also influence the vibration profile.

If the satellite under test is a flight model, it is important to ensure cleanliness during the vibration tests. Two approaches are possible: to place the satellite and the shaker table under a laminar flux of clean (ISO8) air or to perform the tests with the CubeSat inside a tight bag. The first option is preferred because, in the second one, holes have to be practiced in the bag to pass the cables, which can be a potential inlet for contamination.

Small Sats Testing

GET IN TOUCH TODAY!

Want to contract this service? Contact us!

- Converging Commercial-Off-The-Shelf (COTS) and Space-Grade - April 8, 2024

- Wirewound Resistors - April 2, 2024

- Resistors Pulse Load, Power and Voltage Derating - April 2, 2024

0 comments on Vibration Testing for Small Sats